Introduction

Oil resistant power cables are essential components in various industries where exposure to oil and other harsh chemicals is common. These specialized cables are designed to withstand the challenging conditions found in industries such as oil and gas, mining, manufacturing, and transportation. In this comprehensive guide, we will explore the features, benefits, applications, and considerations of oil resistant power cables, shedding light on the crucial role they play in ensuring reliable and safe power transmission in demanding environments.

Chapter 1: Understanding Oil Resistant Power Cables

Oil resistant power cables are specifically engineered to withstand exposure to oils, solvents, chemicals, and other substances that can degrade standard cables. The key feature that sets oil resistant cables apart is their construction using materials that are resistant to the damaging effects of oil and other contaminants. These cables are commonly used in environments where oil spillage or leakage is a risk, such as oil refineries, chemical plants, and industrial manufacturing facilities.

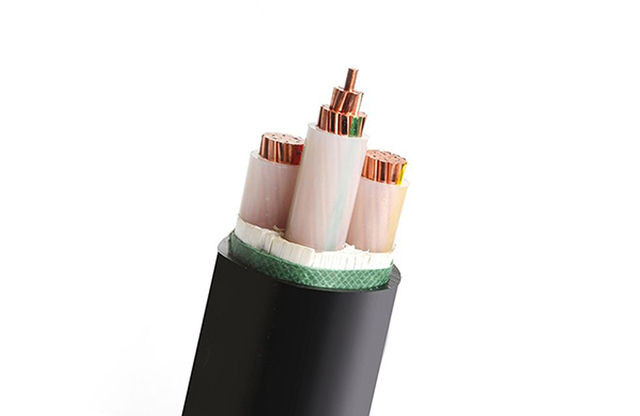

Chapter 2: Construction and Materials

Oil resistant power cables are typically constructed with specialized materials that provide resistance to oil, chemicals, and abrasion. The insulation and jacketing materials used in these cables are carefully selected to ensure durability and longevity in harsh environments. Common materials used in the construction of oil resistant cables include ethylene propylene diene monomer (EPDM), chlorosulfonated polyethylene (CSPE), and cross-linked polyethylene (XLPE), among others.

Chapter 3: Benefits of Oil Resistant Power Cables

The use of oil resistant power cables offers several key benefits, including enhanced safety, reliability, and longevity. These cables are designed to maintain their performance characteristics even when exposed to oil and other contaminants, reducing the risk of electrical faults, short circuits, and downtime. By choosing oil resistant cables, industries can minimize maintenance costs, improve operational efficiency, and ensure a secure power supply in critical applications.

Chapter 4: Applications of Oil Resistant Power Cables

Oil resistant power cables find widespread use in a variety of industries and applications where exposure to oil and chemicals is a concern. Power Cable For Sale include:

1. Oil and gas industry: Oil resistant cables are essential for power transmission in drilling rigs, refineries, and petrochemical plants where exposure to oil and chemicals is prevalent.

2. Mining industry: In mining operations, oil resistant cables are used to power equipment and machinery in harsh underground environments.

3. Industrial manufacturing: Oil resistant cables are employed in manufacturing facilities where oils, solvents, and chemicals are used in production processes.

4. Transportation: Oil resistant cables are utilized in the transportation sector for powering vehicles, trains, and other infrastructure in environments exposed to oil and contaminants.

Chapter 5: Considerations for Choosing Oil Resistant Power Cables

When selecting oil resistant power cables for a specific application, several factors should be considered to ensure optimal performance and longevity. These factors include:

1. Chemical resistance: Verify that the cable materials are compatible with the specific oils and chemicals present in the environment.

2. Temperature rating: Choose cables with a temperature rating suitable for the operating conditions of the application.

3. Mechanical strength: Ensure that the cables have sufficient mechanical strength to withstand bending, pulling, and other stresses.

4. Compliance with standards: Select cables that meet relevant industry standards and certifications for safety and performance.

Chapter 6: Maintenance and Care of Oil Resistant Power Cables

Proper maintenance and care are essential to maximize the lifespan and performance of oil resistant power cables. Regular inspections, testing, and cleaning can help identify potential issues early and prevent costly failures. Additionally, implementing preventive maintenance practices and following manufacturer recommendations for installation and handling can prolong the service life of oil resistant cables.

Conclusion

Oil resistant power cables play a critical role in ensuring reliable and safe power transmission in industries where exposure to oil and chemicals is a concern. By understanding the construction, benefits, applications, considerations, and maintenance of oil resistant cables, industries can make informed decisions when selecting and using these specialized cables. With their resilience and durability, oil resistant power cables continue to be indispensable components in powering essential equipment and machinery in challenging environments.